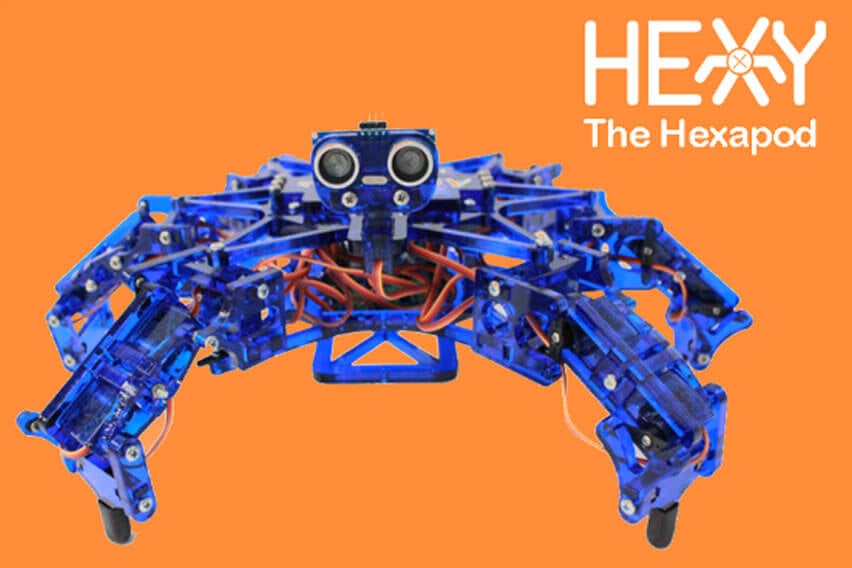

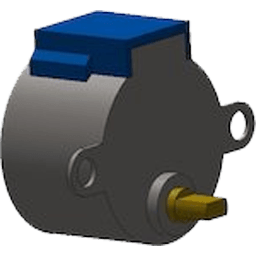

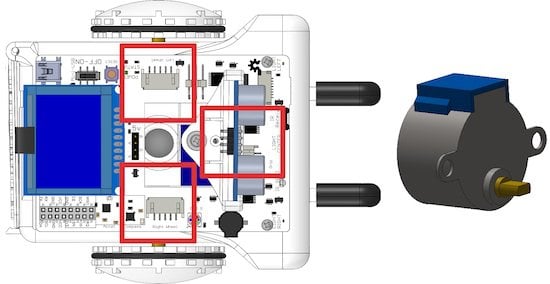

Sparki has three special motors called stepper motors. It has two for the wheels and one in the gripper. They are used to provide precise movement.

How It Works

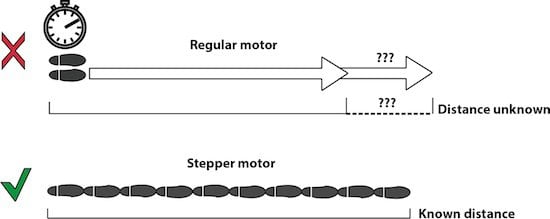

Stepper motors are specially designed to provide predictable movement. Most motors are designed to just spin when they are turned on, and will do so until they are turned off. These motors can spin at different speeds depending on the voltage the are running or how much force they have to overcome, so it is hard to tell how much they have turned.

Stepper motors solve this problem by being designed to only move forward a small, predictable amount each time they are turned on, and they are turned on in steps. This graphic demonstrates how stepper motors move from step to step:

Each time the next step is activated in the stepper, the teeth on the internal gear move forward just a little bit to line up straight with that step’s coil, then stands still as it continues to be pulled towards that step’s coil. Only when that coil is turned off, and the next step’s coil is turned on does it move. Otherwise, it will not move. By counting the steps moved, and multiplying it by the rotation per step, you can measure how much the stepper motor has rotated.

A Walking Analogy

One way to think of how a stepper motor is different from a regular motor is to imagine two people walking.

A regular motor would be like telling a person to walk forward for 1 minute, then guessing how far they moved by guessing how far a normal person walks in 1 minute, without knowing if the person has short legs, is tired, or is a professional runner.

A stepper motor would be like telling a person to carefully walk 10 steps, placing one foot in front of the other toe-to-heel, the measuring 10 steps times the size of their shoe. As long as the person doesn’t miss a step, you can fairly accurately tell the distance they have walked.

Using the Part

Sparki’s stepper motors are used by both its wheels and its gripper.